Cellulase Enzyme

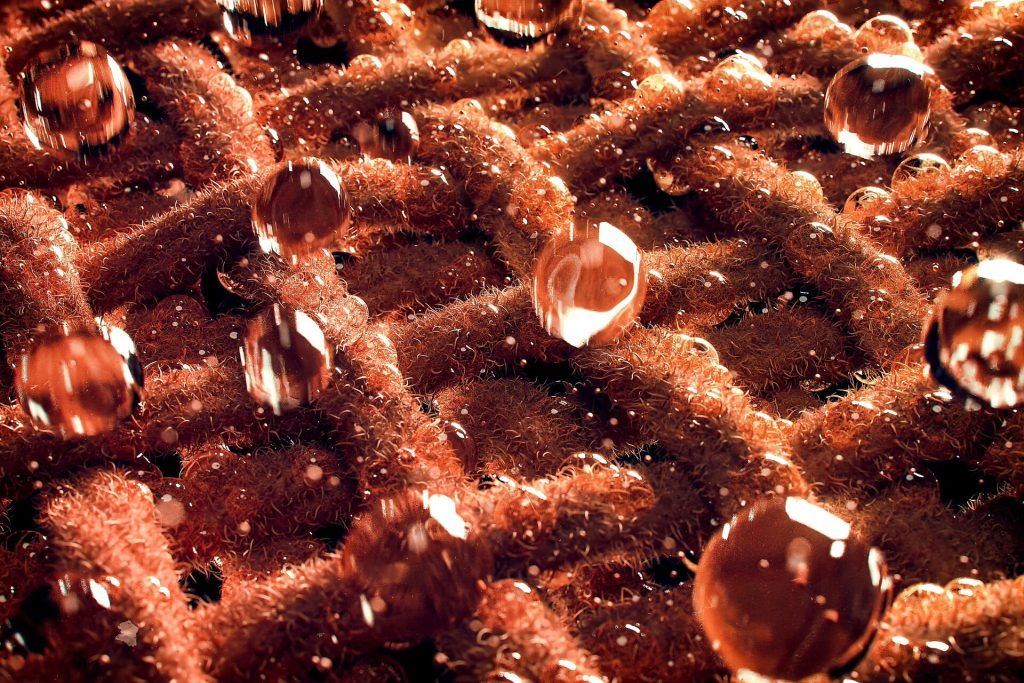

Cellulase enzyme is counted amongst the most important types of enzymes, catalyzing cellulolysis, the decomposition of cellulose of some related polysaccharides. Cellulase enzyme can be used in many fields, such as commercial food processing and also in non-food industries like textile and household cleaning. It also has a long history of use in the pulp and paper industry. Cellulase enzymes has also been used for biofuel production. Being one of the most important types of enzymes it also helps in catalyzing cellulolysis, the decomposition of cellulose, and of some related polysaccharides.

At ultreze enzymes pvt ltd. we strive to merge technology and eco-friendly to provide you with viable biofuel products from various feedstocks.

Cellulase Enzyme for Textile Industries

Ultreze Enzymes is also amongst the leading Textile Enzyme Manufacturers and provides various Enzymes for the Textile Industry. Biotechnology of textile enzymes offers eco-friendly solutions to the textile industry in their processes and applications.

Texozyme-AC and Texozyme-NC are highly concentrating Acid cellulase enzymes and Neutral cellulase enzymes respectively. It is exclusively for bio finishing industry and is used to produce a variety of abrasive effects similar to the Bio-polishing process and finish to Textile garment. It selectively hydrolyzes the micro-fiber terminal of the amorphous region, without damaging the fiber backbone. Treatment with Acid cellulase and neutral cellulase maintains the strength of the fabrics, with thick hand-free and excellent resistance to pilling and fluffing, it provides the fabrics with a high-quality surface. The wide pH range of the enzyme products allows an array of applications and also provides easy combinations with other treatment processes.

| Enzymes | Working pH | Working Temperature | Color |

| Texozyme-AC | 3.5 To 6.5 | 25°c to 65°c | Dark Brown |

| Texozyme-NC | 5.0 To 7.5 | 25°c to 65°c | Dark Brown |

Cellulase Enzyme for Paper and Pulp industries

Cellulase Enzymes has an extensive variety of applications in the paper and pulp industries. It is used for a wide variety of treatments, such as in biomechanical pulping, deinking, and drainage management, manufacturing biodegradable paper towels, sanitary napkins. Cellulase-mediated processes are more economical, energy-saving and, cost-effective with low chlorine consumption. These can also be used as co-additives in pulp bleaching and biomechanical pulping. A combination of cellulase and Hemicellulase is used for deinking of waste papers to improve the quality and give better quality recyclable papers. Cellulases alone, or with xylanases, are advantageous for deinking various kinds of paper wastes. Most applications proposed so far use cellulases and hemicellulases for the release of ink from the fiber surface by fractional hydrolysis of starch particles. It has been hypothesized that enhancements in de-watering and de-inking of different pulps bring about the stripping of the individual fibrils and groups, which have a high proclivity for the encompassing water and ink particles.

Cellulase Enzyme for Conversion of lignocellulosic biomass into ethanol

The conversion of lignocellulosic biomass into ethanol is done with the help of acids and alkaline cellulase Enzymes. Cellulases-mediated hydrolysis is usually preferred basically due to Mediated processes being specific, low energy consuming and eco-friendly and also because its enzymatic nature being preferred over acid/alkali methods. The conversion of biomass into fuel involves the hydrolysis of constituents of raw material to fermentable sugars, followed by sugar fermentation to ethanol by using appropriate microbes. The first step requires degradation of the lignocellulosic polymer to release cellulose and hemicellulose contents, followed by the hydrolysis of carbohydrate polysaccharides to produce free sugars. According to an evaluation, there’s a 39.9% reduction in cost if cellulases are used for bioprocessing and pretreatment.

Cellulase Enzymes for juice industries

Cellulases enzyme when combined with other macerating enzymes can be used for increasing process performance and yield thereby improving the extraction methods, clarification, and stabilization of the juices. They also reduce the viscosity of nectar and puree obtained from fruits such as apricot, mango, plum, papaya, pear, and peach, and can also be used for the extraction of flavonoids from flowers and seeds. Cellulase-mediated extraction is nowadays preferred over conventional methods due to the higher yield, decreased heat damage, and depletion in processing time. Cellulases enzyme can also be used for extracting the phenolic compounds from grape pomace. The structure, flavor, and aroma of fruits and vegetables can be altered using β-Glucosidases in combination with pectinase. They are also reported to reduce the underlying bitterness in citrus fruits and improve their aroma and taste.

Are you looking for enzymes?

We're Here to Assist

Frequently Asked Questions(FAQ)

Cellulase is an enzyme that plays a crucial role in the breakdown of cellulose, a complex carbohydrate found in plant cell walls. Ultrez Enzymes, being a cellulase enzyme, is utilized for its ability to catalyze the hydrolysis of cellulose into smaller sugar molecules.

Cellulase is widely used in various industries such as textiles, biofuel production, and food processing. It helps in the efficient breakdown of plant-based raw materials, enhancing processes like paper manufacturing and bioethanol production.

Yes, Cellulase Enzyme can be employed in waste treatment to break down organic matter, including cellulose-rich waste. This contributes to the decomposition of organic materials and the reduction of environmental impact.

In the textile industry, cellulase enzymes are used to achieve a soft and faded look in denim and other fabrics. The enzyme treatment helps remove surface fuzz and protruding fibers, resulting in a smoother and more comfortable texture.